GARR TOOL offers a variety of different tool coatings, available on certain catalog items. Some coatings can be added to stock items. If a particular coating is not available by either of those options, you can request a quote.

|

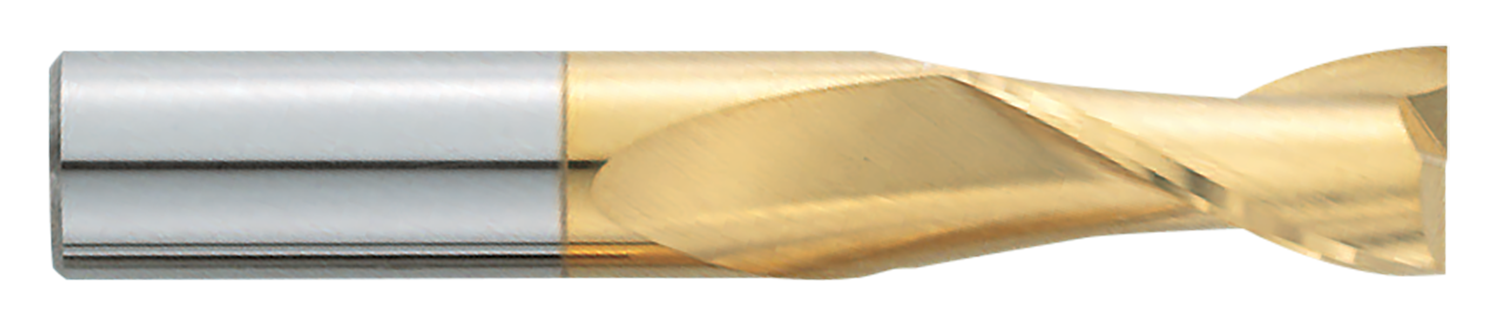

TiN (Titanium Nitride) |

| General purpose coating – low heat resistance. Good lubricity. |

|

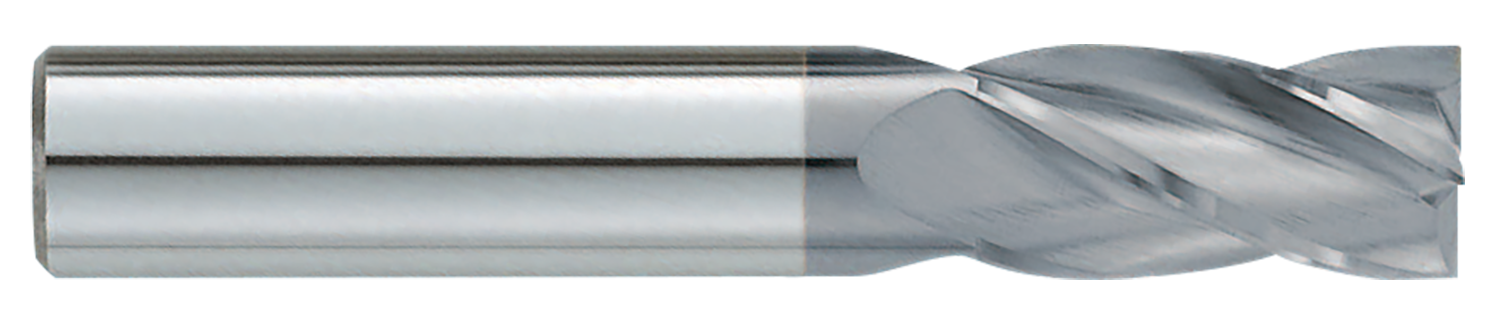

TiCN (Titanium Carbonitride) |

| Good abrasion resistance. Recommended for aluminum, brass, and bronze applications. Low heat resistance – good lubricity. |

|

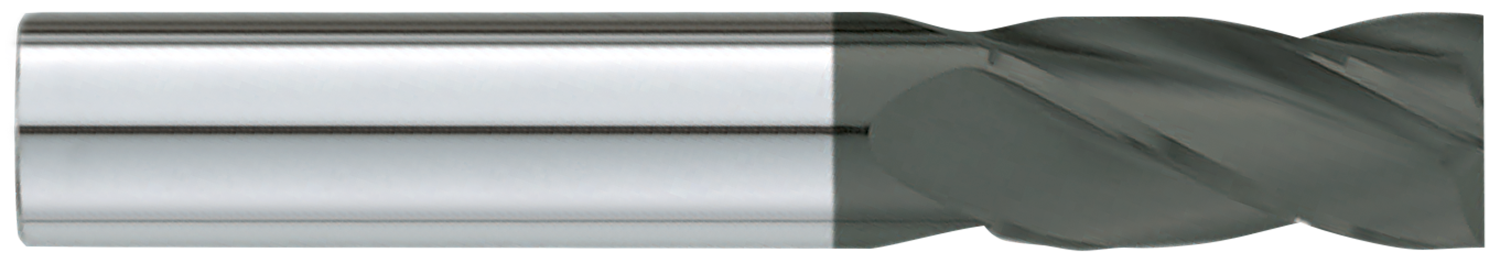

TiAlN (Titanium Aluminum Nitride) |

| Multi-layer coating with good thermal stability for increased speeds and feeds. For semi-dry to dry cutting of most steels, high-nickel alloys, stainless steel and cast iron. Excellent heat resistance, good lubricity. For materials that are 40Rc and under. |

|

AlTiN (Aluminum Titanium) |

| A single-layer coating whose hardness, oxidation resistance and thermal stability were optimized for material hardness above 38Rc and high-speed machining of materials that are difficult to work (titanium alloys, Inconel). |

|

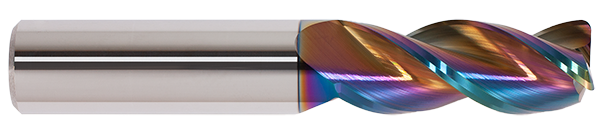

ALUMASTAR® (Titanium Diboride – TiB2) |

| A thin film coating with a low affinity for aluminum, ideal for machining aluminum alloys. The resistance to adhesion of aluminum allows higher speeds or feeds. Coating thickness is intentionally kept lower in order to maintain a sharp edge. |

|

CRYSTALLINE DIAMOND (CVD) |

| Improved productivity in composites. Excellent choice for cutting graphite and fiberglass. Can be added to a special for milling or drilling applications. |

|

AlCrN (Aluminum Chromium) |

| Aluminum Chromium-based coatings have excellent wear resistance, thermal shock stability, and hot hardness. Well suited for Titanium, Inconel, and carbon fiber. |

|

HARDLUBE |

| Multi-layer coating with thermal stability and lubricating properties needed for the drilling of steels, high-nickel alloys, stainless steel, cast iron, aluminum, brass, and bronze. Excellent heat resistance, great lubricity. |

|

AlTiN-based |

| Greater abrasion resistance, extra shear strength, lower adhesion tendency, maximum toughness and a very smooth surface achieve a quantum leap in drilling performance. This coating is particularly advantageous for carbide drills. With its unique nanostructure, AlTiN plus AlCrN, it boosts productivity in various materials. |

|

AlCrN-based |

| High wear resistance even under severe thermal stress. Revolutionary smooth coating with outstanding adhesion. Prevents sticking and build-up on edges. Precise high-performance coating. Maintains sharp edges. Primarily for high-temp alloys, stainless, and tool steels. |